HOW ARGUX PPF IS MADE

TRANSFORMING RAW TPU INTO FILM BUILT TO ENDURE REAL ROADS.

STEP 3

Self-Healing Top Coating

A high performance nano ceramic top coat is added, giving the film heat activated self healing properties, stronger stain resistance, and exceptional clarity over time.

STEP 4

PET Protective Lamination

We laminate the film with a stabilising PET protective layer, ensuring strength during handling and perfectly preserving the surface until installation.

STEP 5

Curing, Cutting & Packaging

Every layer undergoes a controlled curing cycle, then the film is cut into 15m × 1.52m rolls, inspected for quality, and packaged for distribution.

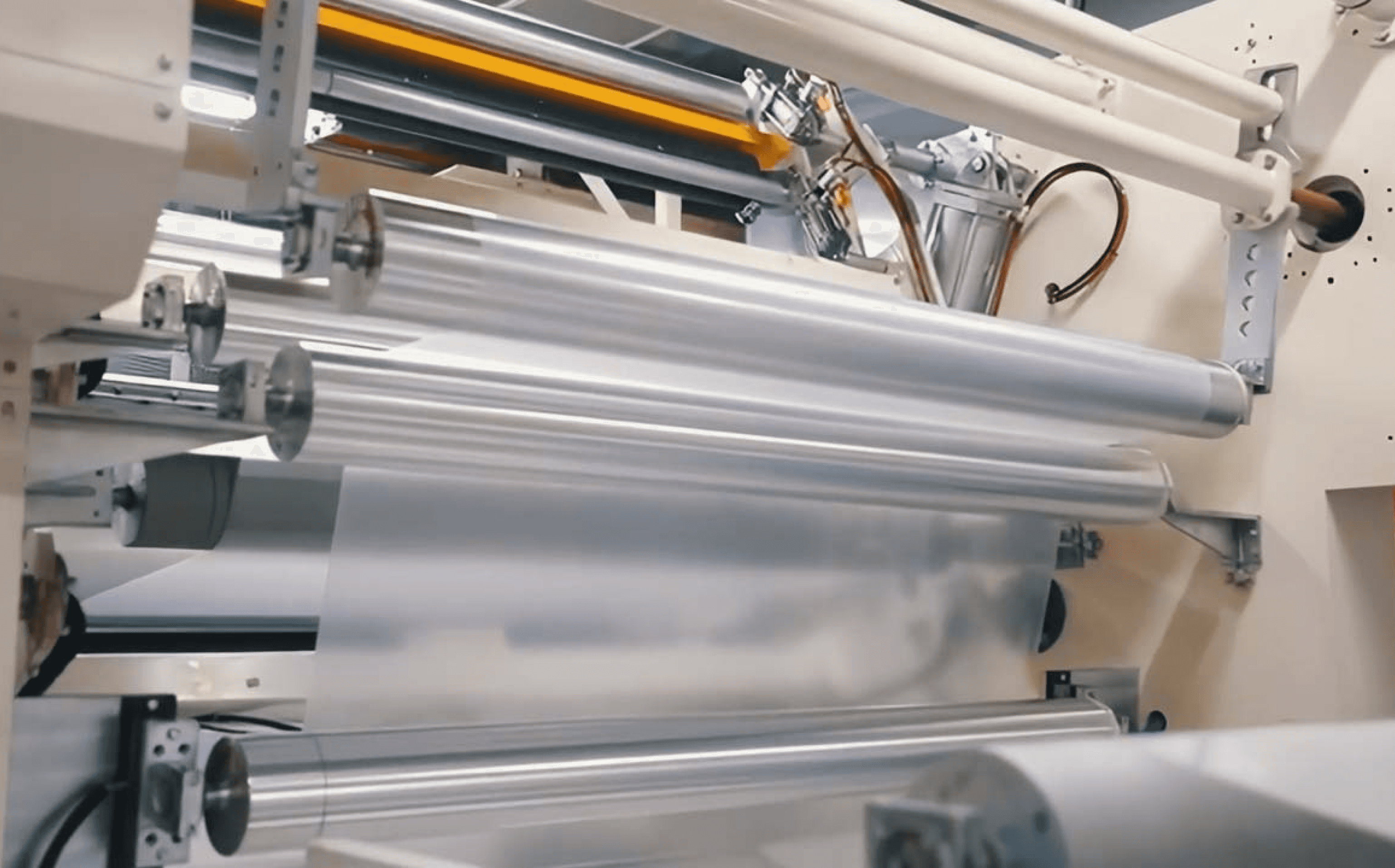

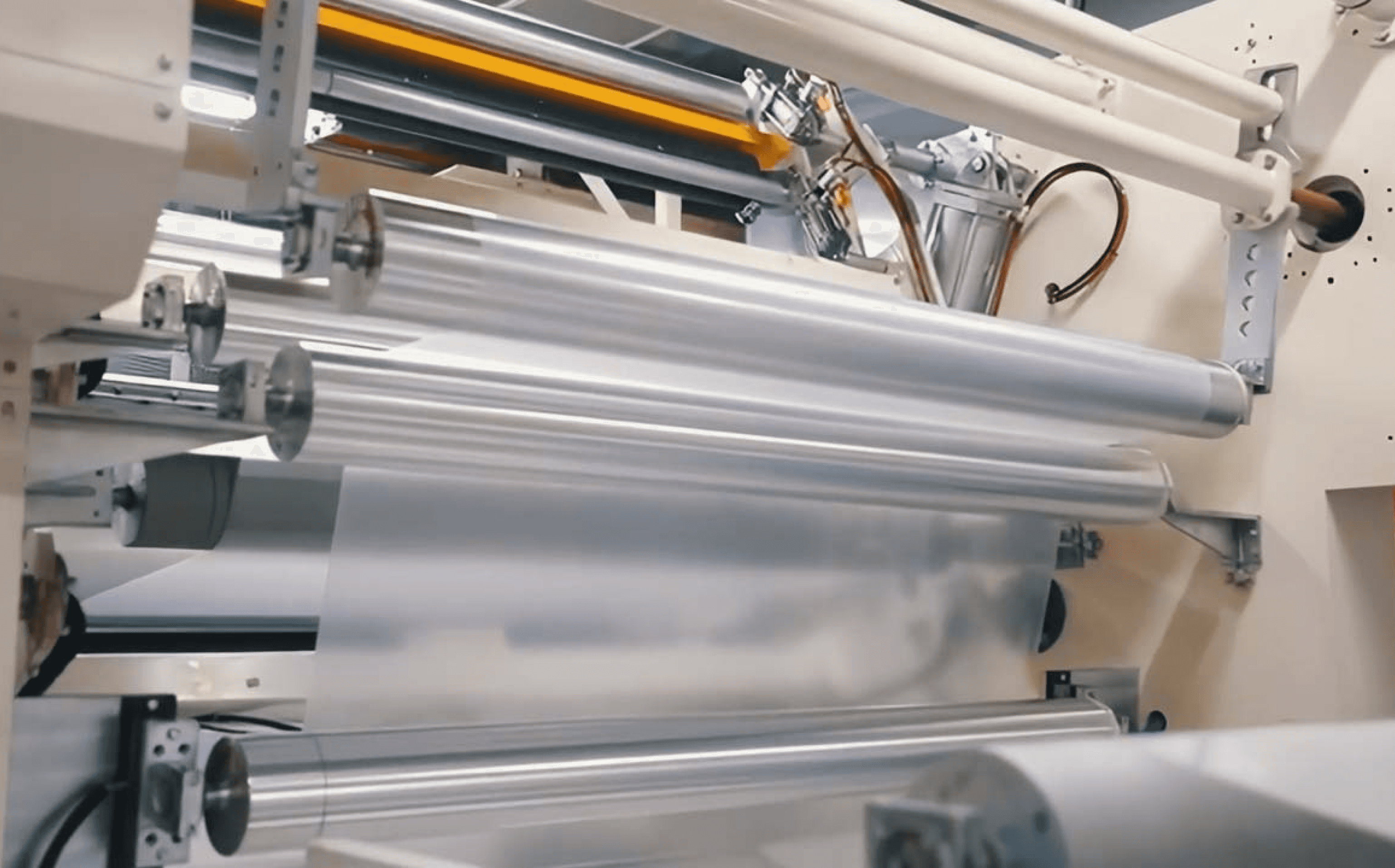

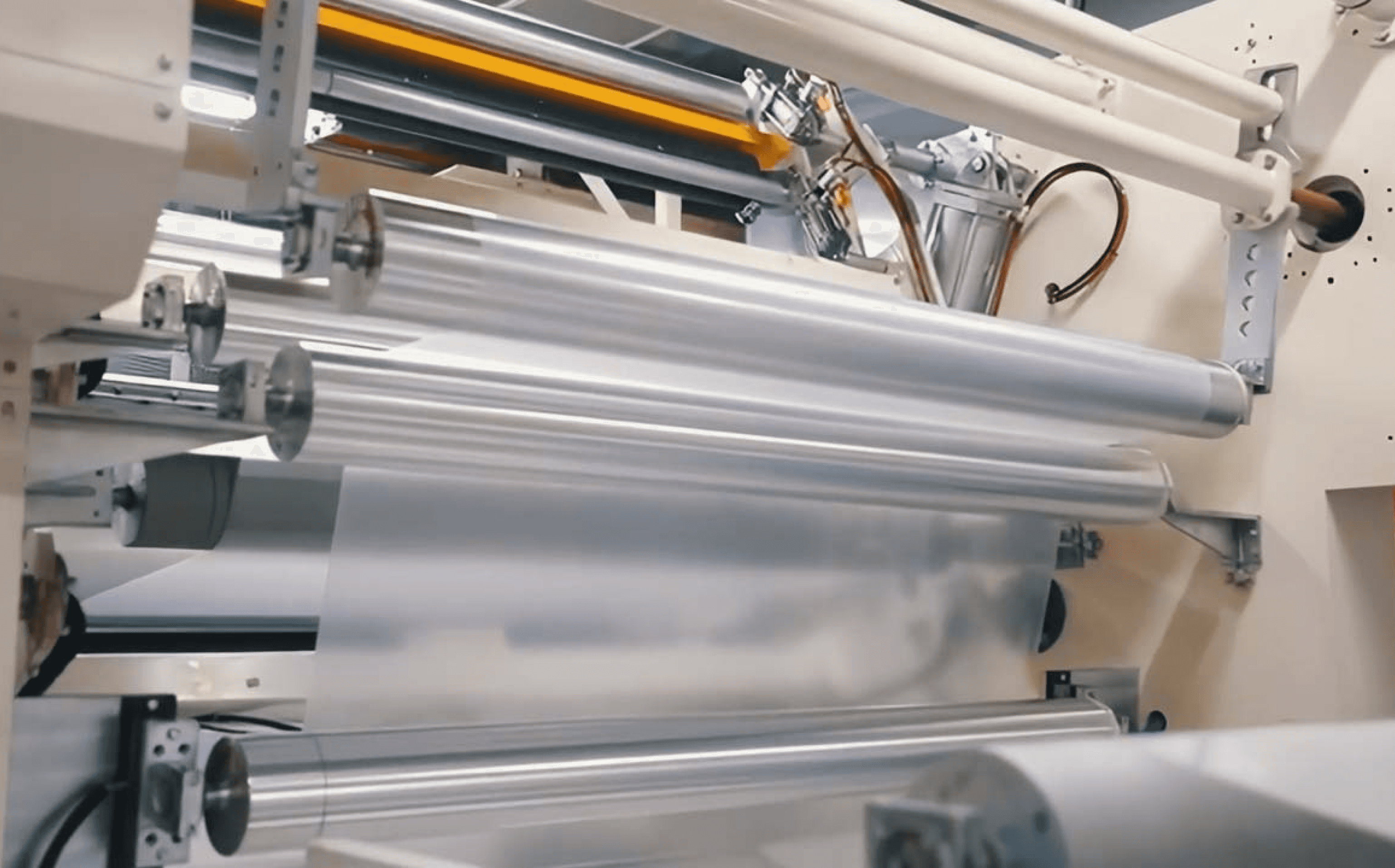

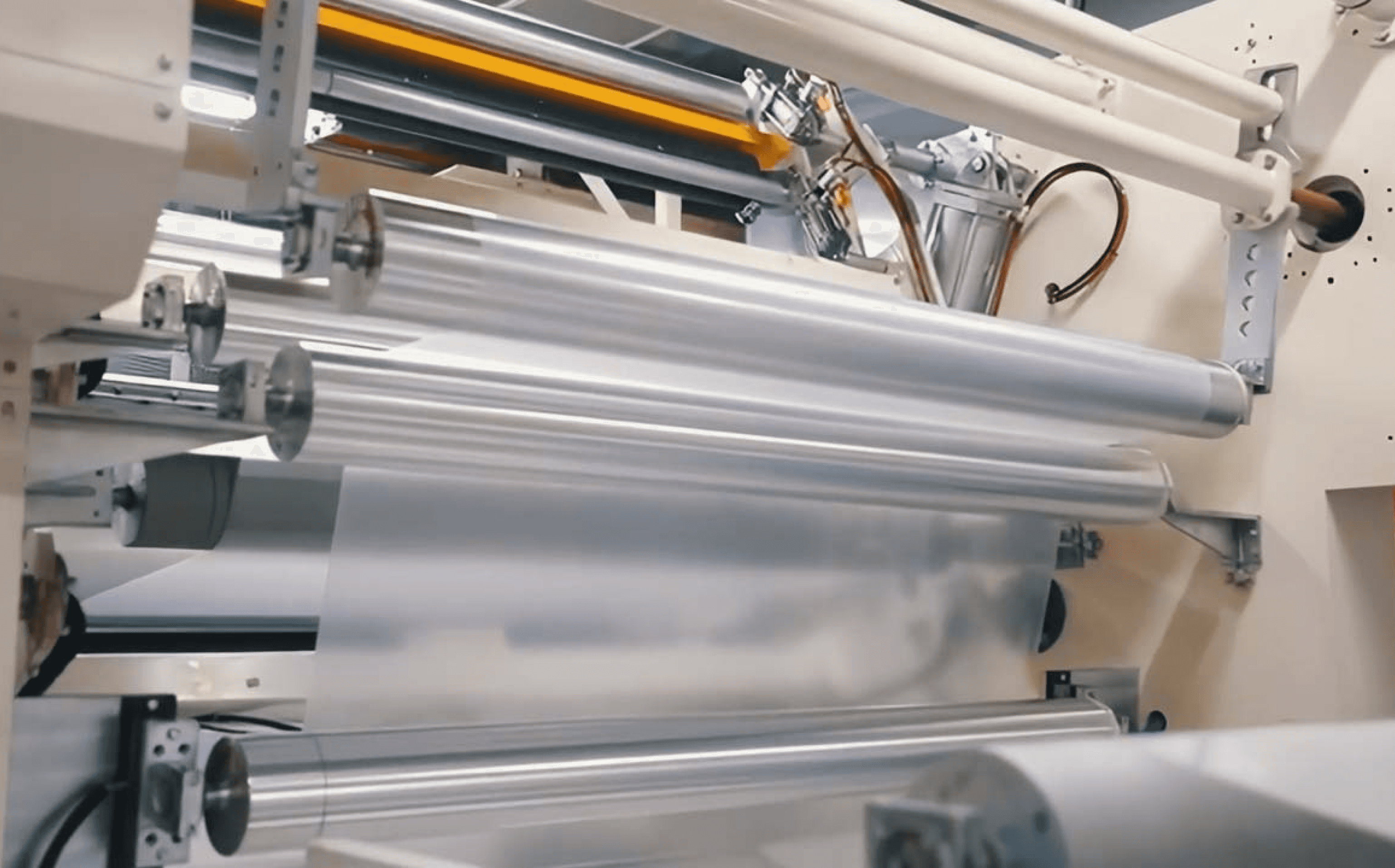

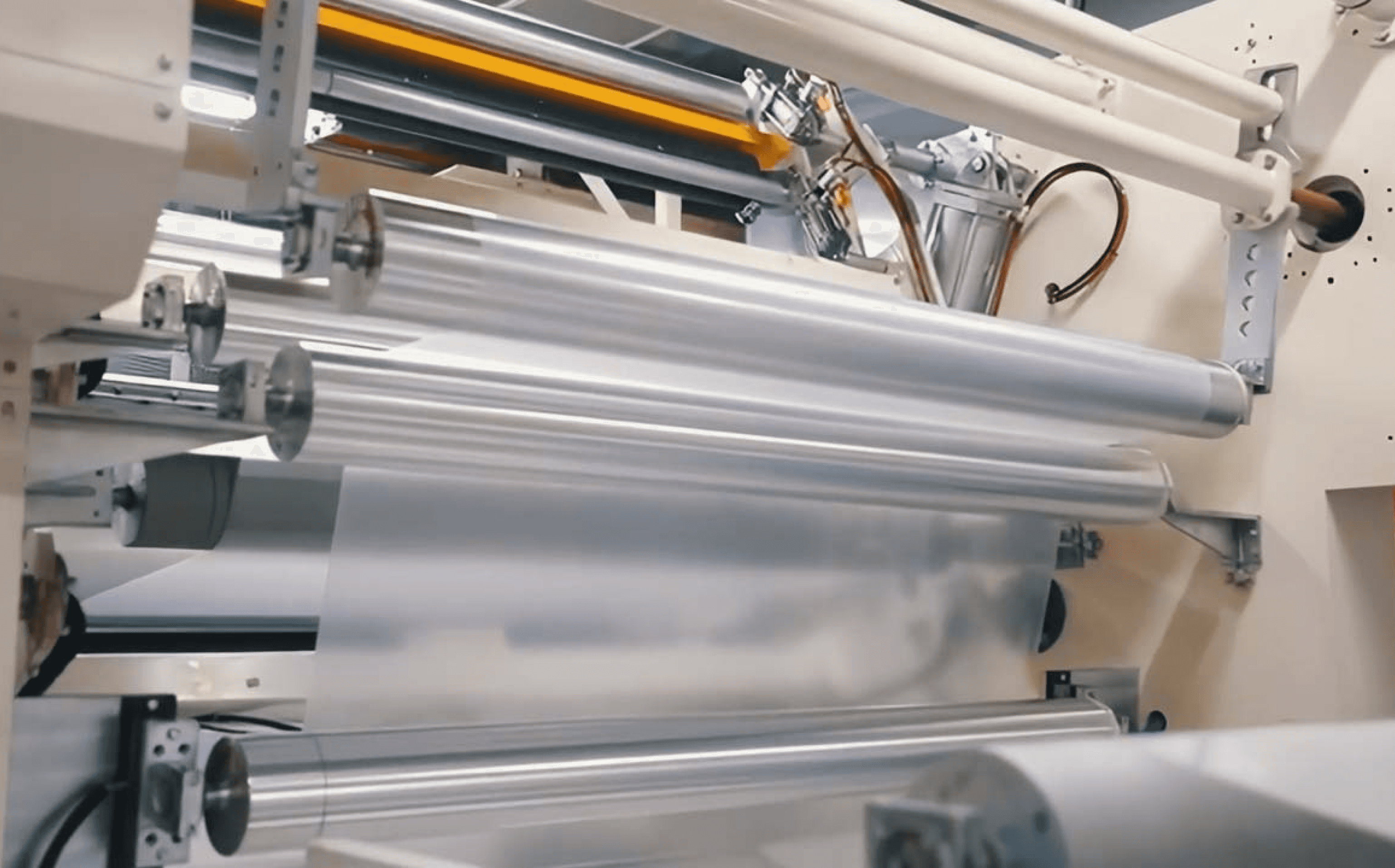

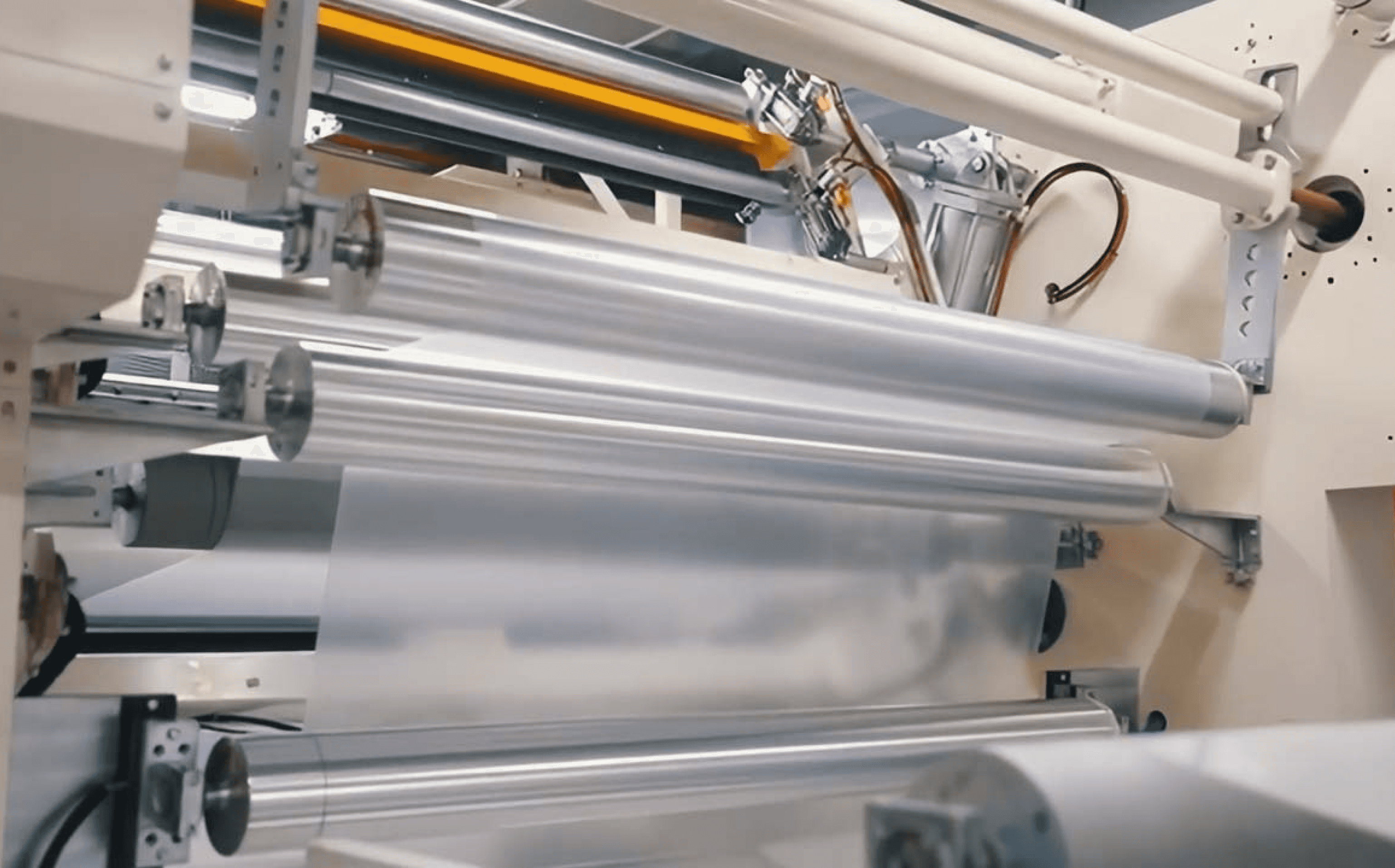

STEP 1

TPU Extrusion

We begin with German engineered BASF aliphatic TPU, melted and extruded into a flawless 605 meter sheet. This forms the foundation of every ARGUX film pure, strong, and optically clear.

STEP 1

TPU Extrusion

We begin with German engineered BASF aliphatic TPU, melted and extruded into a flawless 605 meter sheet. This forms the foundation of every ARGUX film pure, strong, and optically clear.

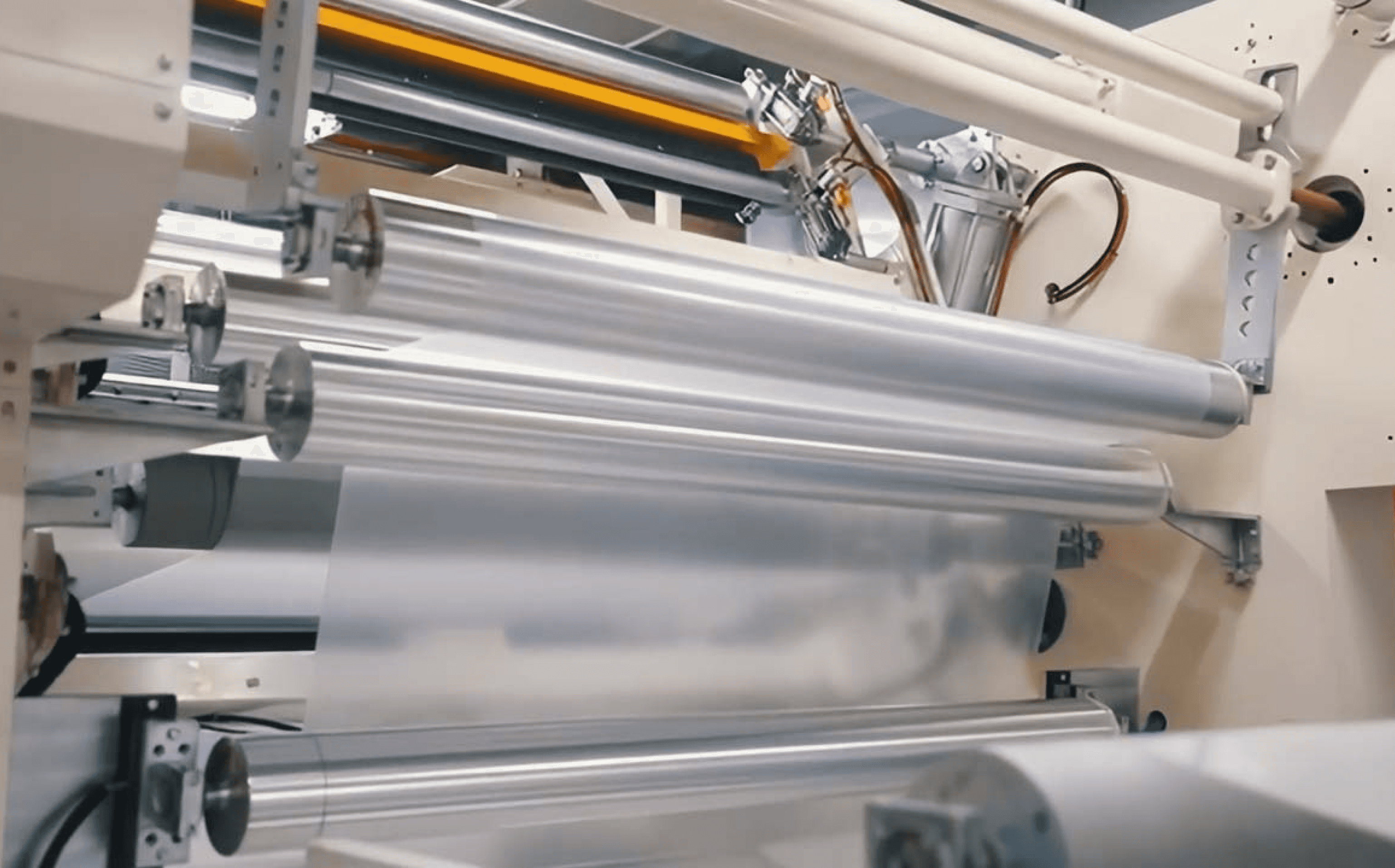

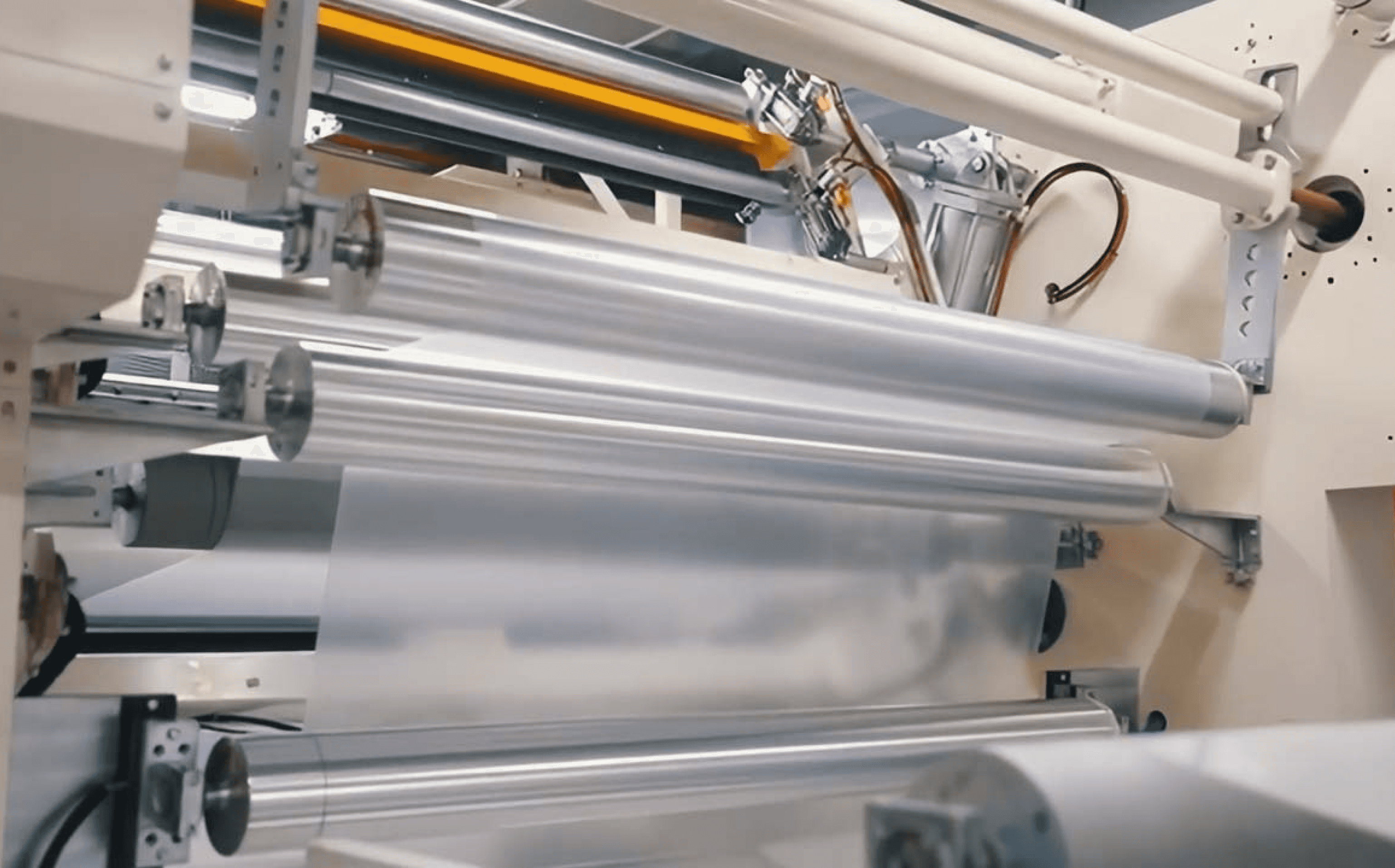

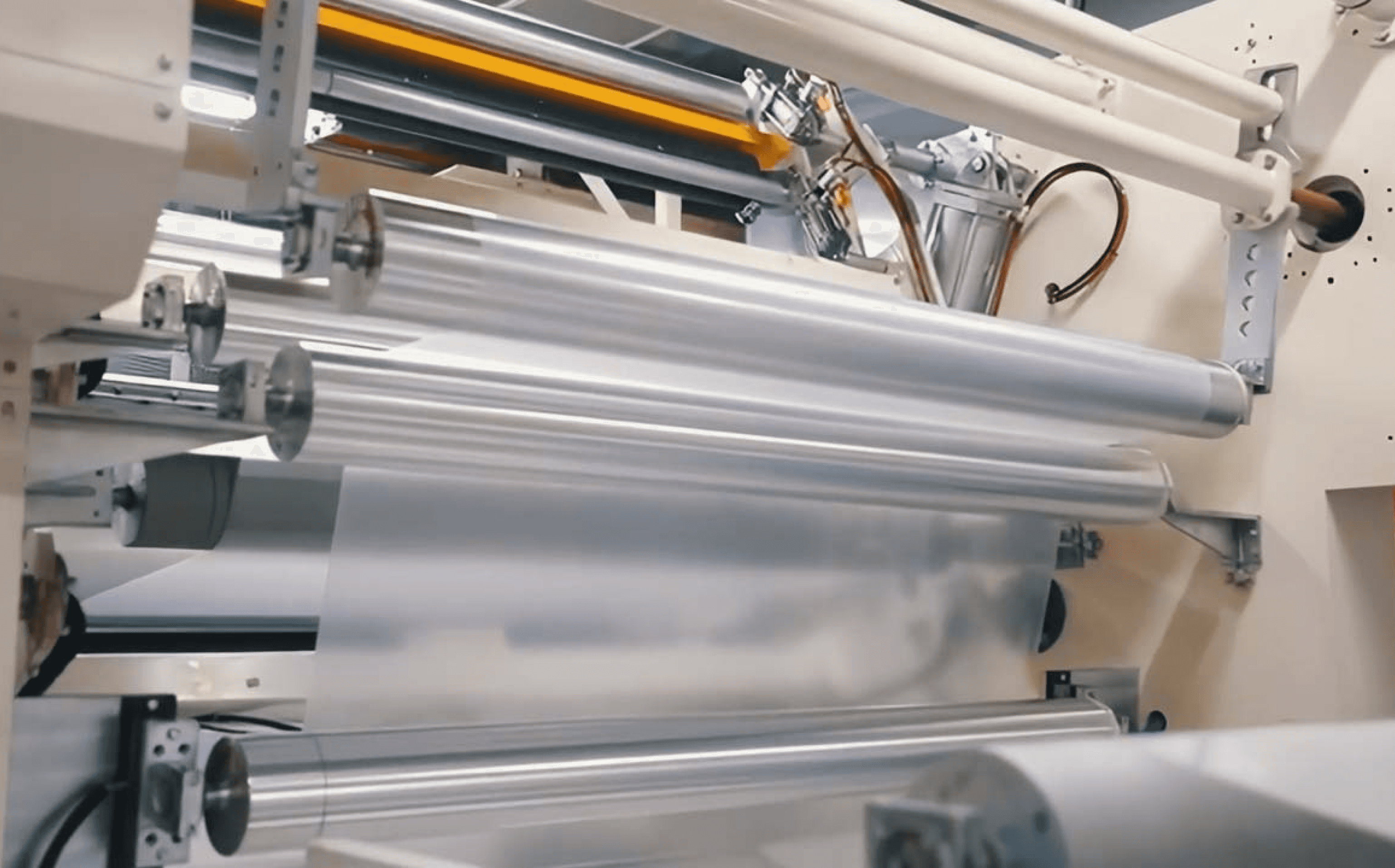

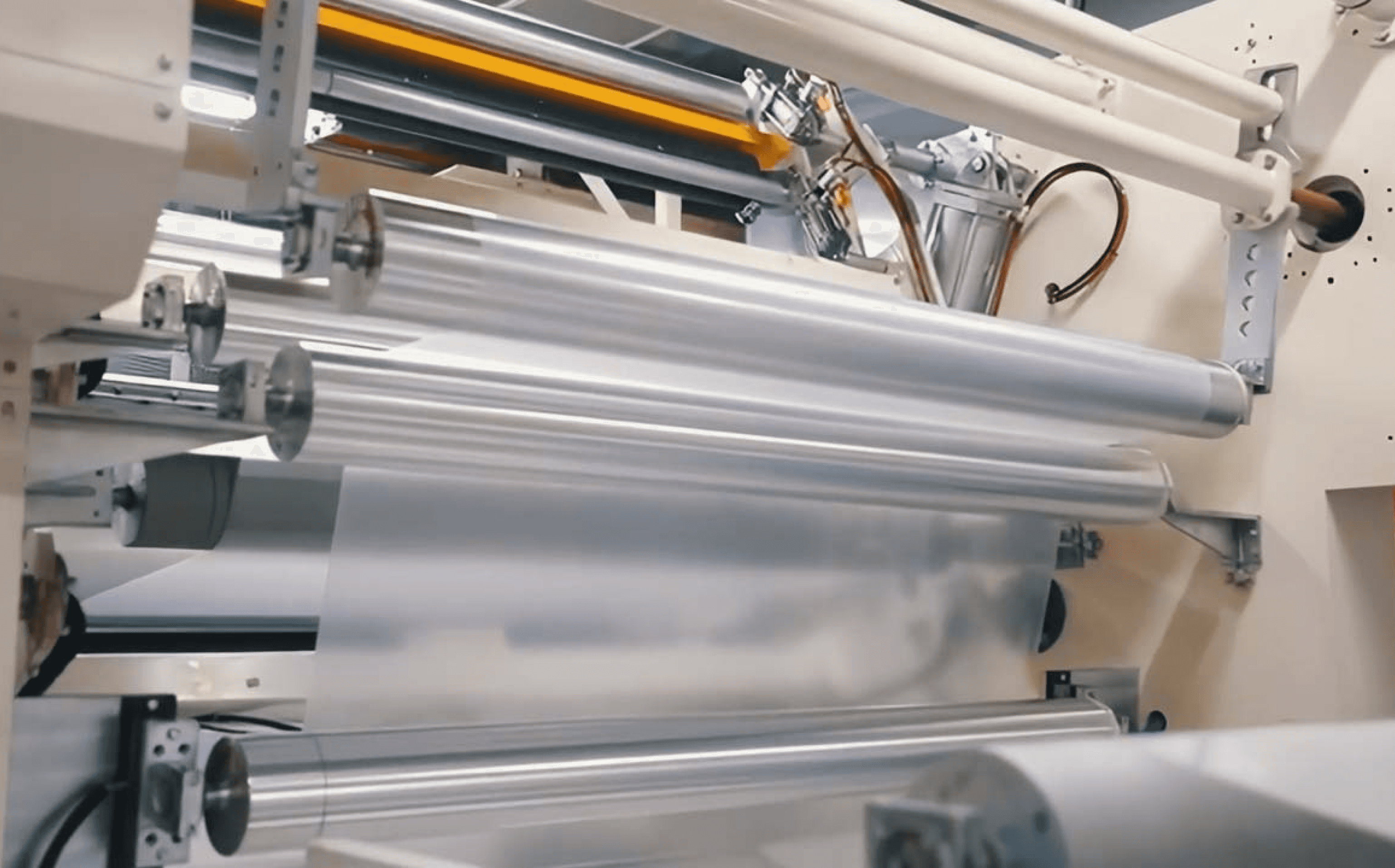

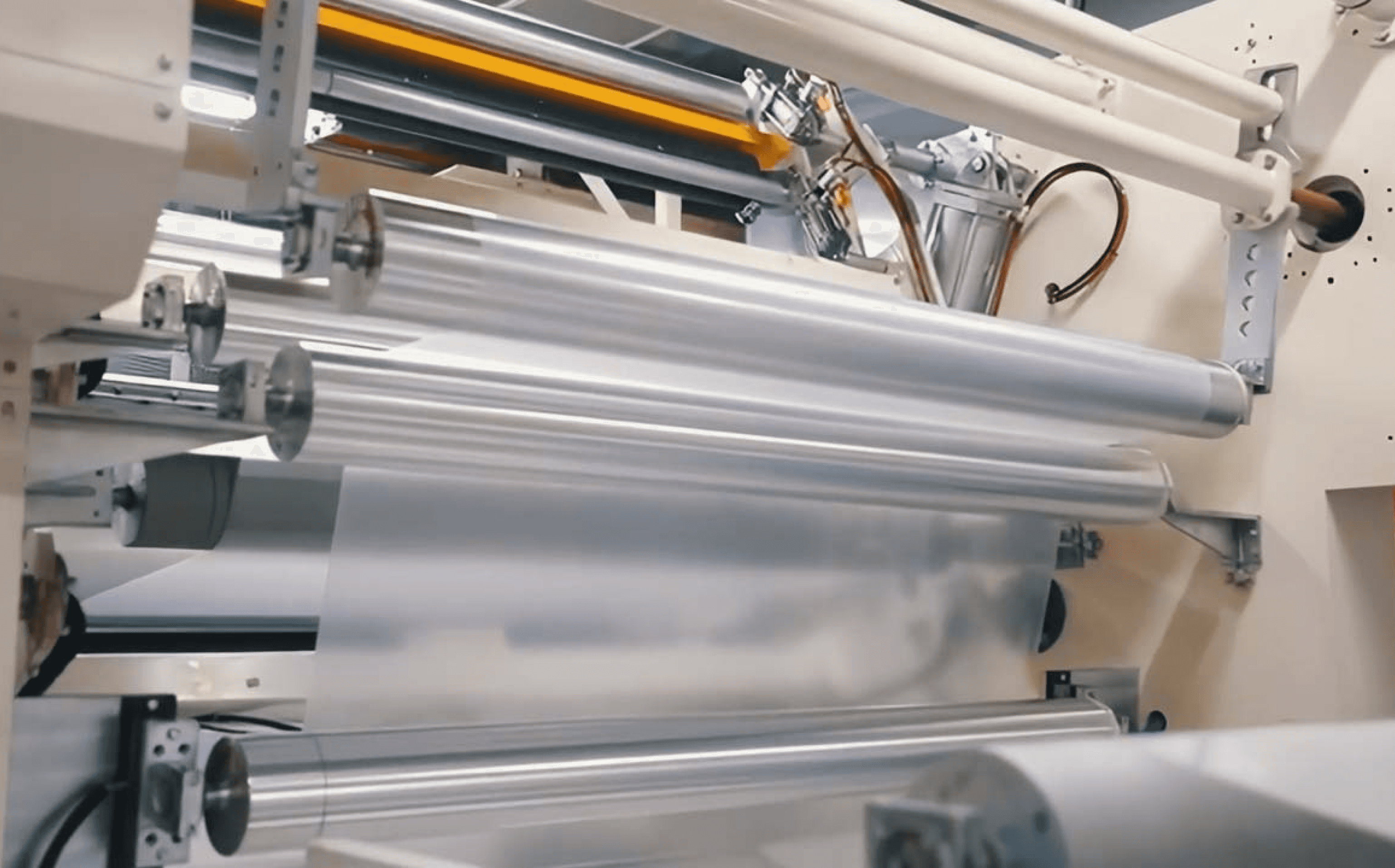

STEP 2

Adhesive Coating

The TPU sheet moves into a dedicated coating line where a precision applied high bond acrylic adhesive is deposited, engineered for clean installation, strong adhesion, and long term durability.

STEP 2

Adhesive Coating

The TPU sheet moves into a dedicated coating line where a precision applied high bond acrylic adhesive is deposited, engineered for clean installation, strong adhesion, and long term durability.

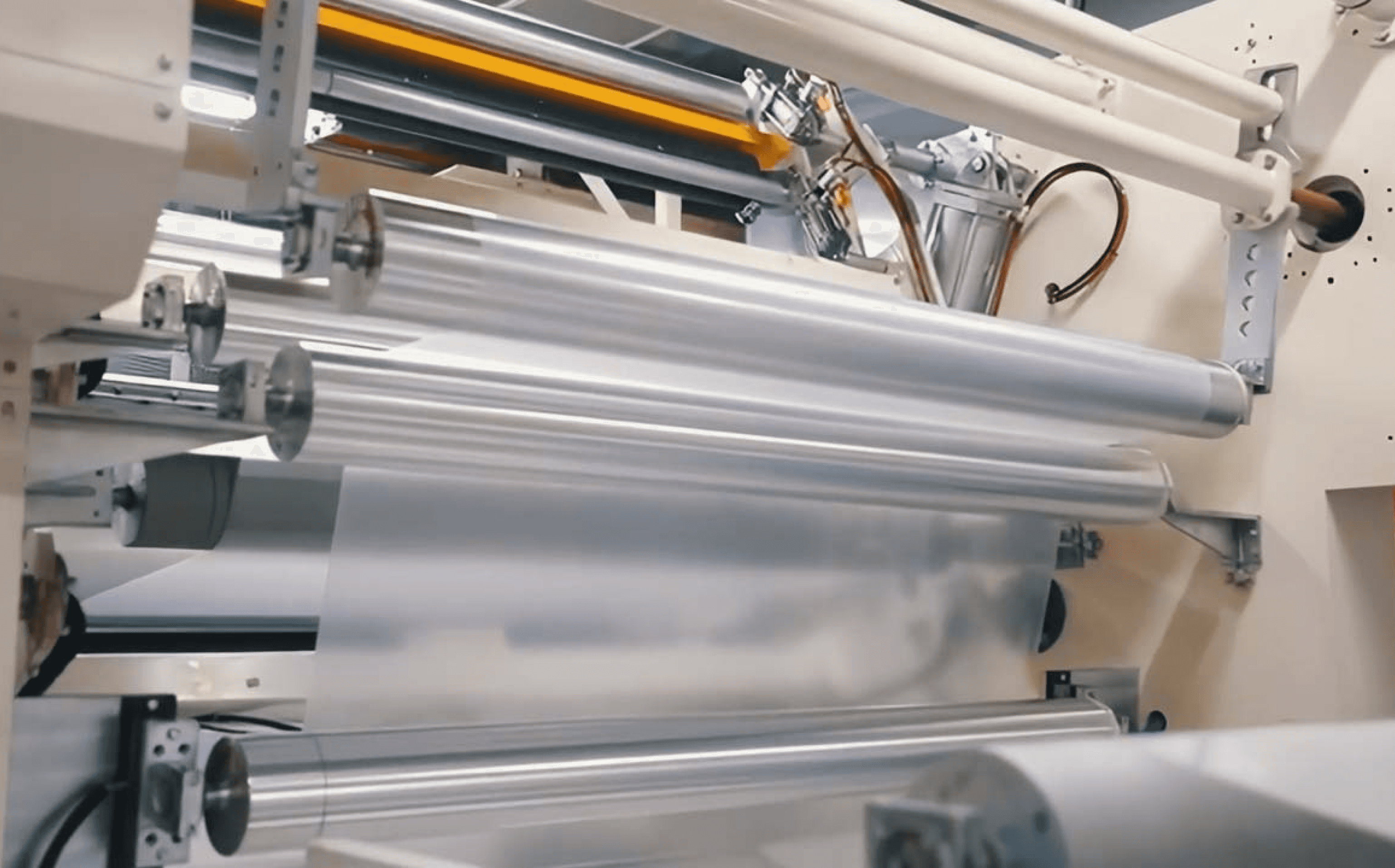

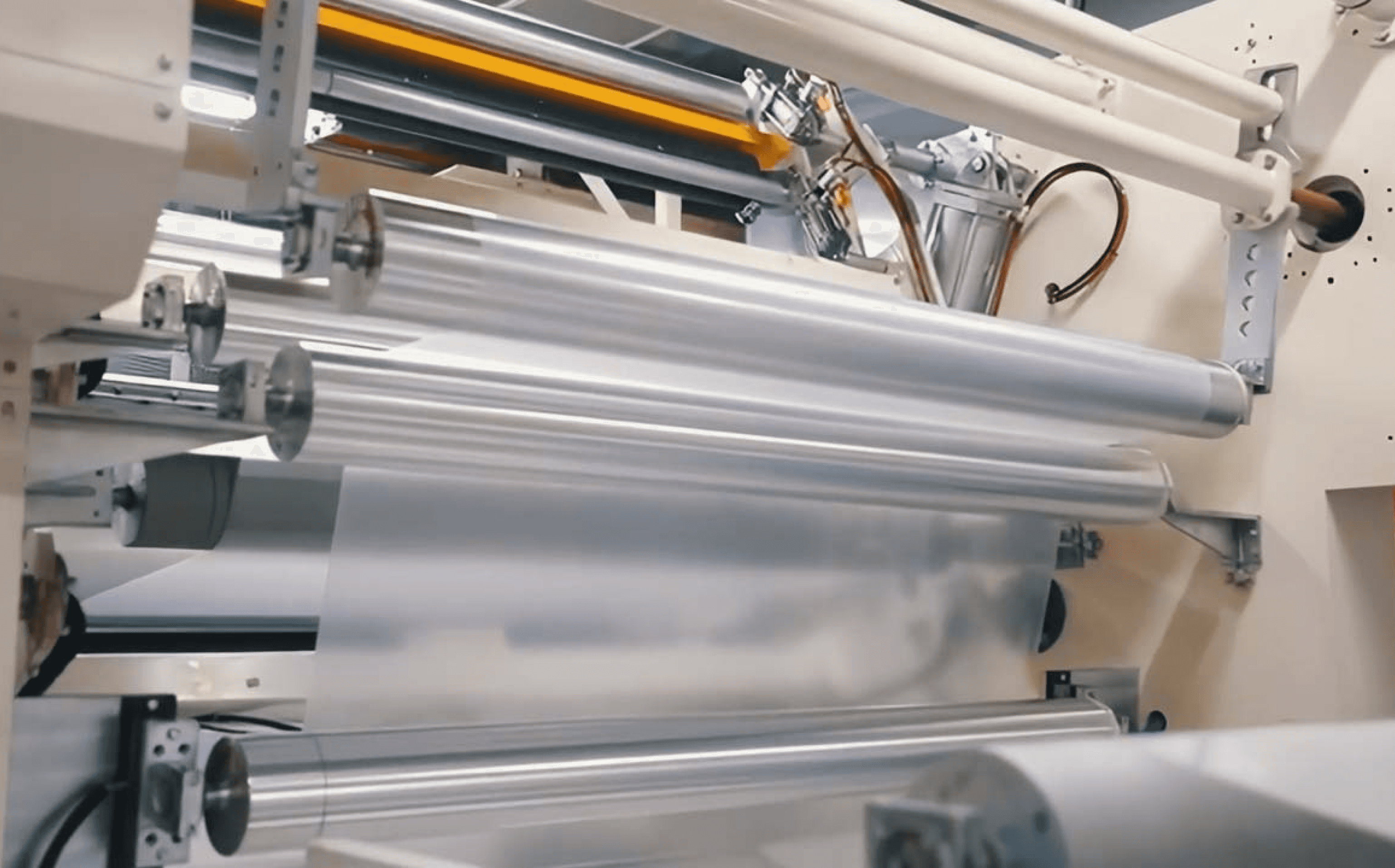

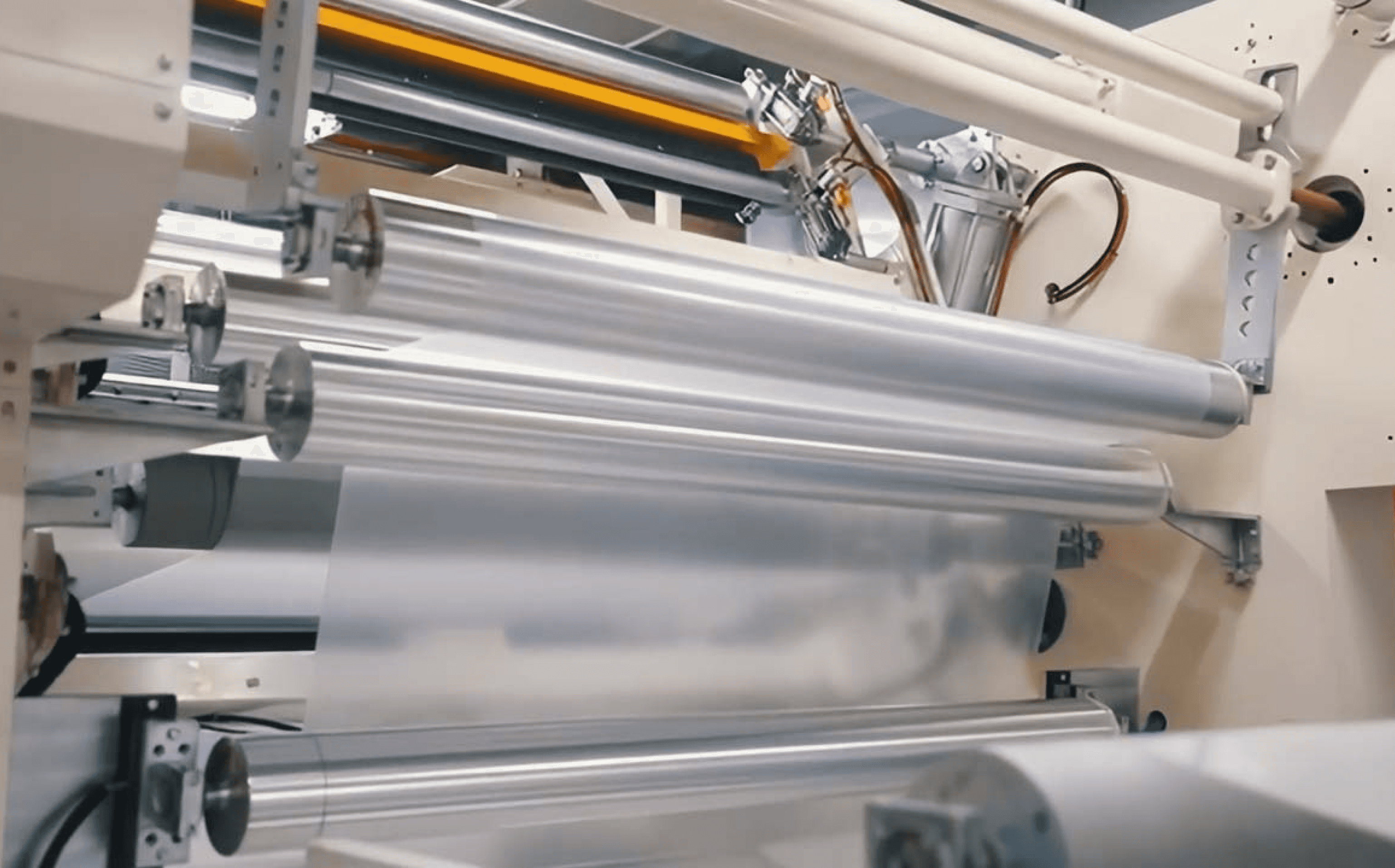

STEP 3

Self-Healing Top Coating

A high performance nano ceramic top coat is added, giving the film heat activated self healing properties, stronger stain resistance, and exceptional clarity over time.

STEP 3

Self-Healing Top Coating

A high performance nano ceramic top coat is added, giving the film heat activated self healing properties, stronger stain resistance, and exceptional clarity over time.

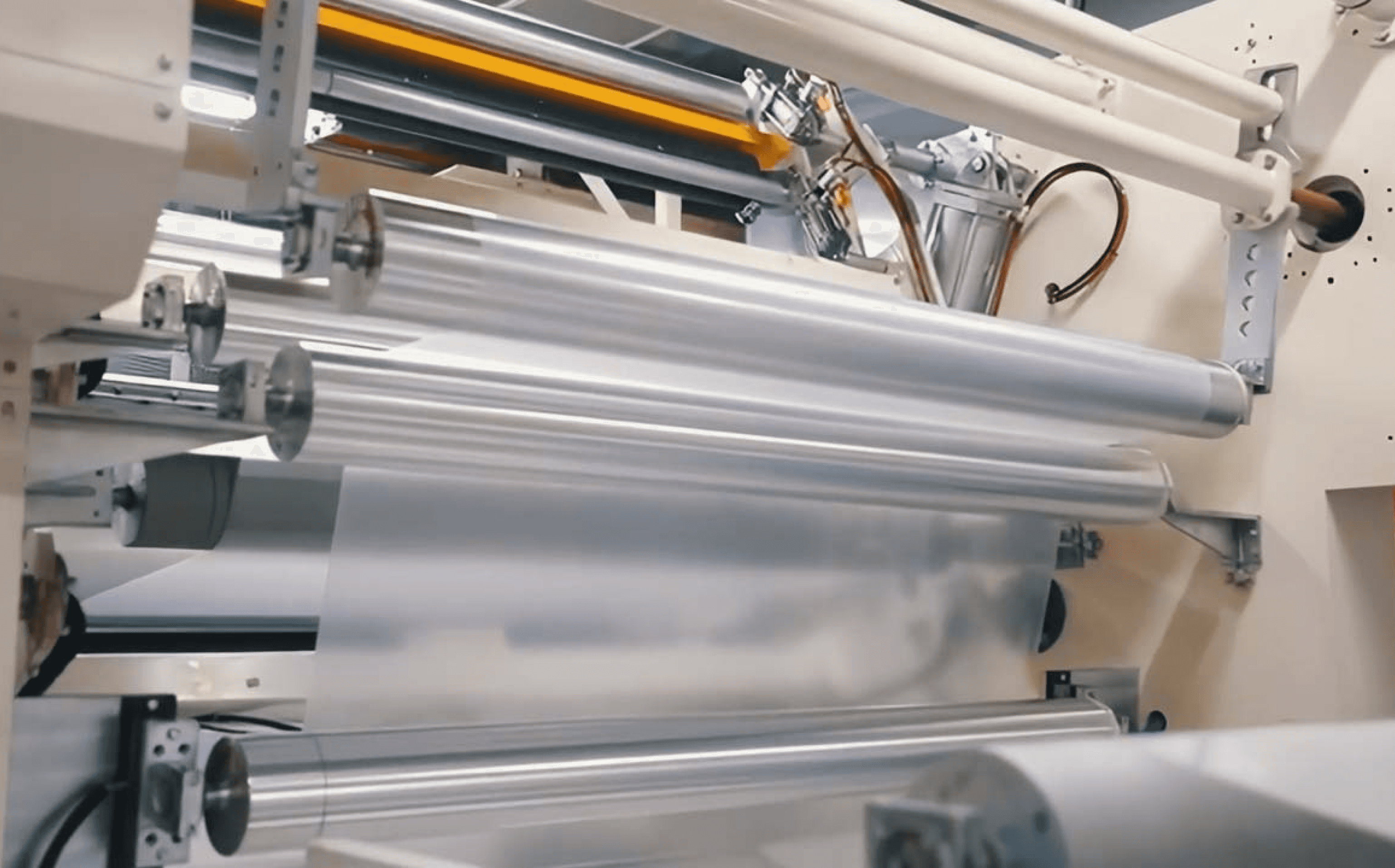

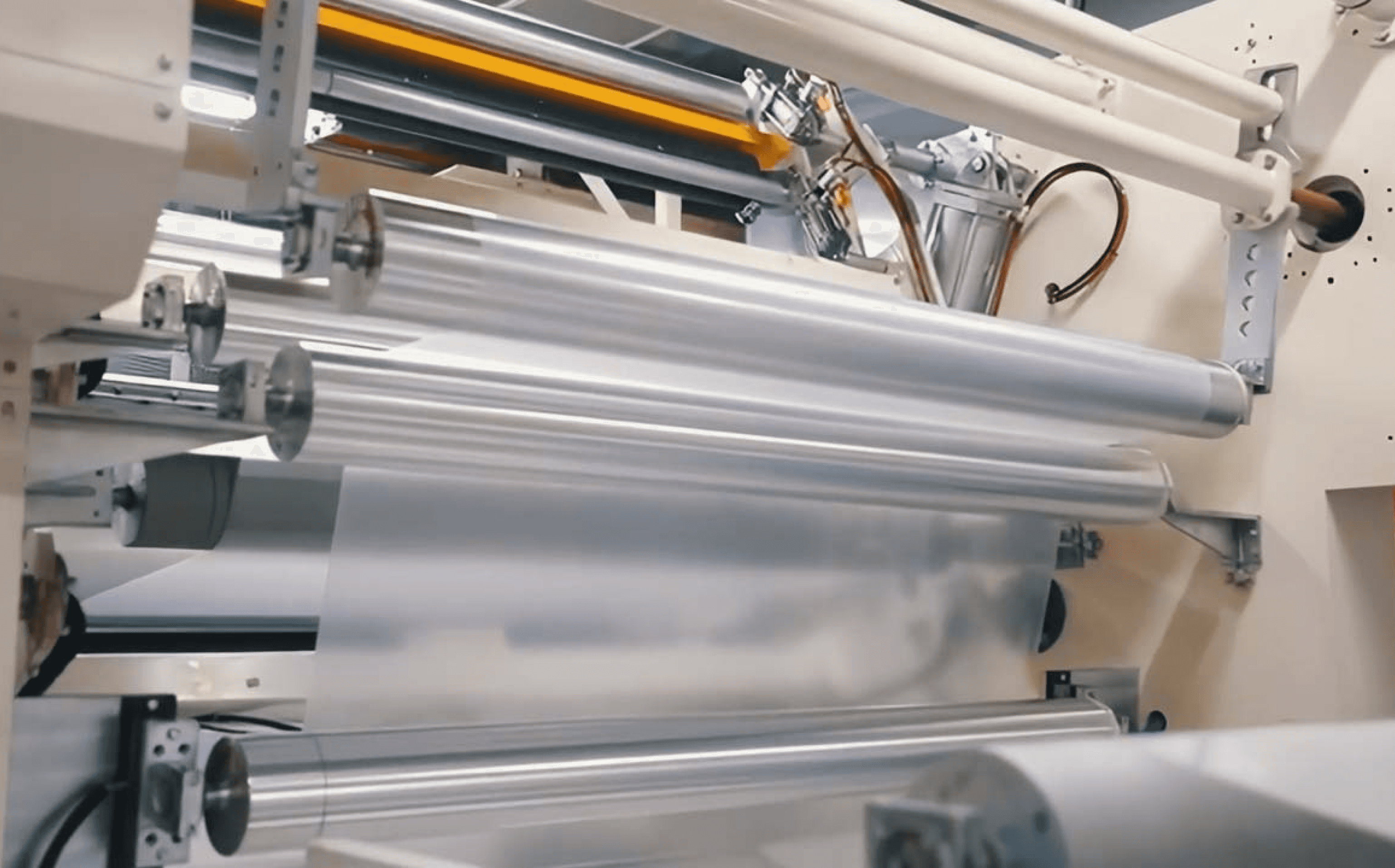

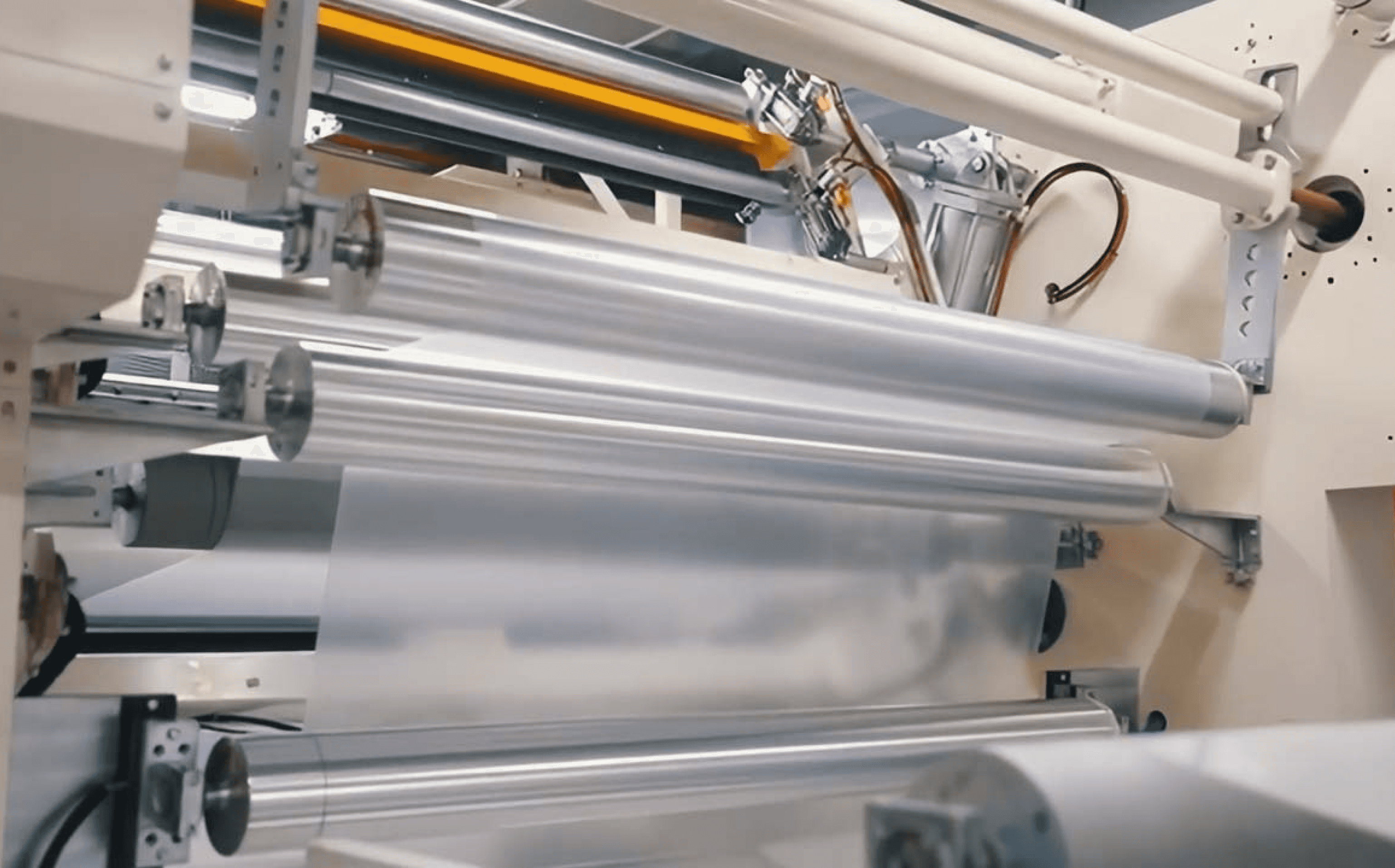

STEP 4

PET Protective Lamination

We laminate the film with a stabilising PET protective layer, ensuring strength during handling and perfectly preserving the surface until installation.

STEP 4

PET Protective Lamination

We laminate the film with a stabilising PET protective layer, ensuring strength during handling and perfectly preserving the surface until installation.

STEP 5

Curing, Cutting & Packaging

Every layer undergoes a controlled curing cycle, then the film is cut into 15m × 1.52m rolls, inspected for quality, and packaged for distribution.

STEP 5

Curing, Cutting & Packaging

Every layer undergoes a controlled curing cycle, then the film is cut into 15m × 1.52m rolls, inspected for quality, and packaged for distribution.

STEP 2

Adhesive Coating

The TPU sheet moves into a dedicated coating line where a precision applied high bond acrylic adhesive is deposited, engineered for clean installation, strong adhesion, and long term durability.

STEP 1

TPU Extrusion

We begin with German engineered BASF aliphatic TPU, melted and extruded into a flawless 605 meter sheet. This forms the foundation of every ARGUX film - pure, strong, and optically clear.

STEP 2

Adhesive Coating

The TPU sheet moves into a dedicated coating line where a precision applied high bond acrylic adhesive is deposited, engineered for clean installation, strong adhesion, and long term durability.

STEP 4

PET Protective Lamination

We laminate the film with a stabilising PET protective layer, ensuring strength during handling and perfectly preserving the surface until installation.

STEP 5

Curing, Cutting & Packaging

Every layer undergoes a controlled curing cycle, then the film is cut into 15m × 1.52m rolls, inspected for quality, and packaged for distribution.

STEP 1

TPU Extrusion

We begin with German engineered BASF aliphatic TPU, melted and extruded into a flawless 605 meter sheet. This forms the foundation of every ARGUX film - pure, strong, and optically clear.

STEP 3

Self-Healing Top Coating

A high performance nano ceramic top coat is added, giving the film heat activated self healing properties, stronger stain resistance, and exceptional clarity over time.

STEP 1

TPU Extrusion

We begin with German engineered BASF aliphatic TPU, melted and extruded into a flawless 605 meter sheet. This forms the foundation of every ARGUX film — pure, strong, and optically clear.

STEP 2

Adhesive Coating

The TPU sheet moves into a dedicated coating line where a precision applied high bond acrylic adhesive is deposited, engineered for clean installation, strong adhesion, and long term durability.

STEP 3

Self-Healing Top Coating

A high performance nano ceramic top coat is added, giving the film heat activated self healing properties, stronger stain resistance, and exceptional clarity over time.

STEP 4

PET Protective Lamination

We laminate the film with a stabilising PET protective layer, ensuring strength during handling and perfectly preserving the surface until installation.

STEP 5

Curing, Cutting & Packaging

Every layer undergoes a controlled curing cycle, then the film is cut into 15m × 1.52m rolls, inspected for quality, and packaged for distribution.

STEP 1

TPU Extrusion

We begin with German engineered BASF aliphatic TPU, melted and extruded into a flawless 605 meter sheet. This forms the foundation of every ARGUX film — pure, strong, and optically clear.

STEP 2

Adhesive Coating

The TPU sheet moves into a dedicated coating line where a precision applied high bond acrylic adhesive is deposited, engineered for clean installation, strong adhesion, and long term durability.

STEP 3

Self-Healing Top Coating

A high performance nano ceramic top coat is added, giving the film heat activated self healing properties, stronger stain resistance, and exceptional clarity over time.

STEP 4

PET Protective Lamination

We laminate the film with a stabilising PET protective layer, ensuring strength during handling and perfectly preserving the surface until installation.

STEP 5

Curing, Cutting & Packaging

Every layer undergoes a controlled curing cycle, then the film is cut into 15m × 1.52m rolls, inspected for quality, and packaged for distribution.

STEP 1

TPU Extrusion

We begin with German engineered BASF aliphatic TPU, melted and extruded into a flawless 605 meter sheet. This forms the foundation of every ARGUX film — pure, strong, and optically clear.

STEP 2

Adhesive Coating

The TPU sheet moves into a dedicated coating line where a precision applied high bond acrylic adhesive is deposited, engineered for clean installation, strong adhesion, and long term durability.

STEP 3

Self-Healing Top Coating

A high performance nano ceramic top coat is added, giving the film heat activated self healing properties, stronger stain resistance, and exceptional clarity over time.

STEP 4

PET Protective Lamination

We laminate the film with a stabilising PET protective layer, ensuring strength during handling and perfectly preserving the surface until installation.

STEP 5

Curing, Cutting & Packaging

Every layer undergoes a controlled curing cycle, then the film is cut into 15m × 1.52m rolls, inspected for quality, and packaged for distribution.

STEP 1

TPU Extrusion

We begin with German engineered BASF aliphatic TPU, melted and extruded into a flawless 605 meter sheet. This forms the foundation of every ARGUX film — pure, strong, and optically clear.

STEP 2

Adhesive Coating

The TPU sheet moves into a dedicated coating line where a precision applied high bond acrylic adhesive is deposited, engineered for clean installation, strong adhesion, and long term durability.

STEP 3

Self-Healing Top Coating

A high performance nano ceramic top coat is added, giving the film heat activated self healing properties, stronger stain resistance, and exceptional clarity over time.

STEP 4

PET Protective Lamination

We laminate the film with a stabilising PET protective layer, ensuring strength during handling and perfectly preserving the surface until installation.

STEP 5

Curing, Cutting & Packaging

Every layer undergoes a controlled curing cycle, then the film is cut into 15m × 1.52m rolls, inspected for quality, and packaged for distribution.

WHY INHOUSE

Built by Us. Controlled by Us. Perfected by Us.

Total Material Control

We select every ingredient from German-made TPU to our adhesive formulation ensuring consistent clarity, strength, and long-term performance.

precison at every step

We select every ingredient from German-made TPU to our adhesive formulation ensuring consistent clarity, strength, and long-term performance.

Better durability and Stability

In-house production guarantees uniform thickness, clarity, and adhesive performance — giving installers predictable results and drivers long-term reliability.

Consistency across every roll

In-house production guarantees uniform thickness, clarity, and adhesive performance — giving installers predictable results and drivers long-term reliability.

Total Material Control

We select every ingredient from German-made TPU to our adhesive formulation ensuring consistent clarity, strength, and long-term performance.

Precison at every step

We select every ingredient from German-made TPU to our adhesive formulation ensuring consistent clarity, strength, and long-term performance.

Total Material Control

We begin with German engineered BASF aliphatic TPU, melted and extruded into a flawless 605 meter sheet. This forms the foundation of every ARGUX film pure, strong, and optically clear.

Precison at every step

Extrusion, coating, curing, and cutting all happen under one roof. Nothing is left to chance, and every layer meets our internal standards.

Better durability and Stability

In-house production guarantees uniform thickness, clarity, and adhesive performance — giving installers predictable results and drivers long-term reliability.

Consistency across every roll

In-house production guarantees uniform thickness, clarity, and adhesive performance — giving installers predictable results and drivers long-term reliability.

Better durability and Stability

In-house production allows us to fine tune UV resistance, healing speed, stain resistance, and elasticity for harsher climates like Australia.

Consistency across every roll

In-house production guarantees uniform thickness, clarity, and adhesive performance — giving installers predictable results and drivers long-term reliability.

WHY INHOUSE

Built by Us. Controlled by Us. Perfected by Us.

Total Material Control

We begin with German engineered BASF aliphatic TPU, melted and extruded into a flawless 605 meter sheet. This forms the foundation of every ARGUX film pure, strong, and optically clear.

Precison at every step

Extrusion, coating, curing, and cutting all happen under one roof. Nothing is left to chance, and every layer meets our internal standards.

Precison at every step

Extrusion, coating, curing, and cutting all happen under one roof. Nothing is left to chance, and every layer meets our internal standards.

Better durability and Stability

In-house production allows us to fine tune UV resistance, healing speed, stain resistance, and elasticity for harsher climates like Australia.

Consistency across every roll

In-house production guarantees uniform thickness, clarity, and adhesive performance giving installers predictable results and drivers long term reliability.

Consistency across every roll

In-house production guarantees uniform thickness, clarity, and adhesive performance giving installers predictable results and drivers long term reliability.

WHY INHOUSE

Built by Us. Controlled by Us. Perfected by Us.

Total Material Control

We begin with German engineered BASF aliphatic TPU, melted and extruded into a flawless 605 meter sheet. This forms the foundation of every ARGUX film pure, strong, and optically clear.

Precison at every step

Extrusion, coating, curing, and cutting all happen under one roof. Nothing is left to chance, and every layer meets our internal standards.

Better durability and Stability

In-house production allows us to fine tune UV resistance, healing speed, stain resistance, and elasticity for harsher climates like Australia.

Consistency across every roll

In-house production guarantees uniform thickness, clarity, and adhesive performance giving installers predictable results and drivers long term reliability.

WHY INHOUSE

Built by Us. Controlled by Us. Perfected by Us.

Total Material Control

We begin with German engineered BASF aliphatic TPU, melted and extruded into a flawless 605 meter sheet. This forms the foundation of every ARGUX film pure, strong, and optically clear.

Precison at every step

Extrusion, coating, curing, and cutting all happen under one roof. Nothing is left to chance, and every layer meets our internal standards.

Precison at every step

Extrusion, coating, curing, and cutting all happen under one roof. Nothing is left to chance, and every layer meets our internal standards.

Better durability and Stability

In-house production allows us to fine tune UV resistance, healing speed, stain resistance, and elasticity for harsher climates like Australia.

Consistency across every roll

In-house production guarantees uniform thickness, clarity, and adhesive performance — giving installers predictable results and drivers long-term reliability.

Consistency across every roll

In-house production guarantees uniform thickness, clarity, and adhesive performance — giving installers predictable results and drivers long-term reliability.

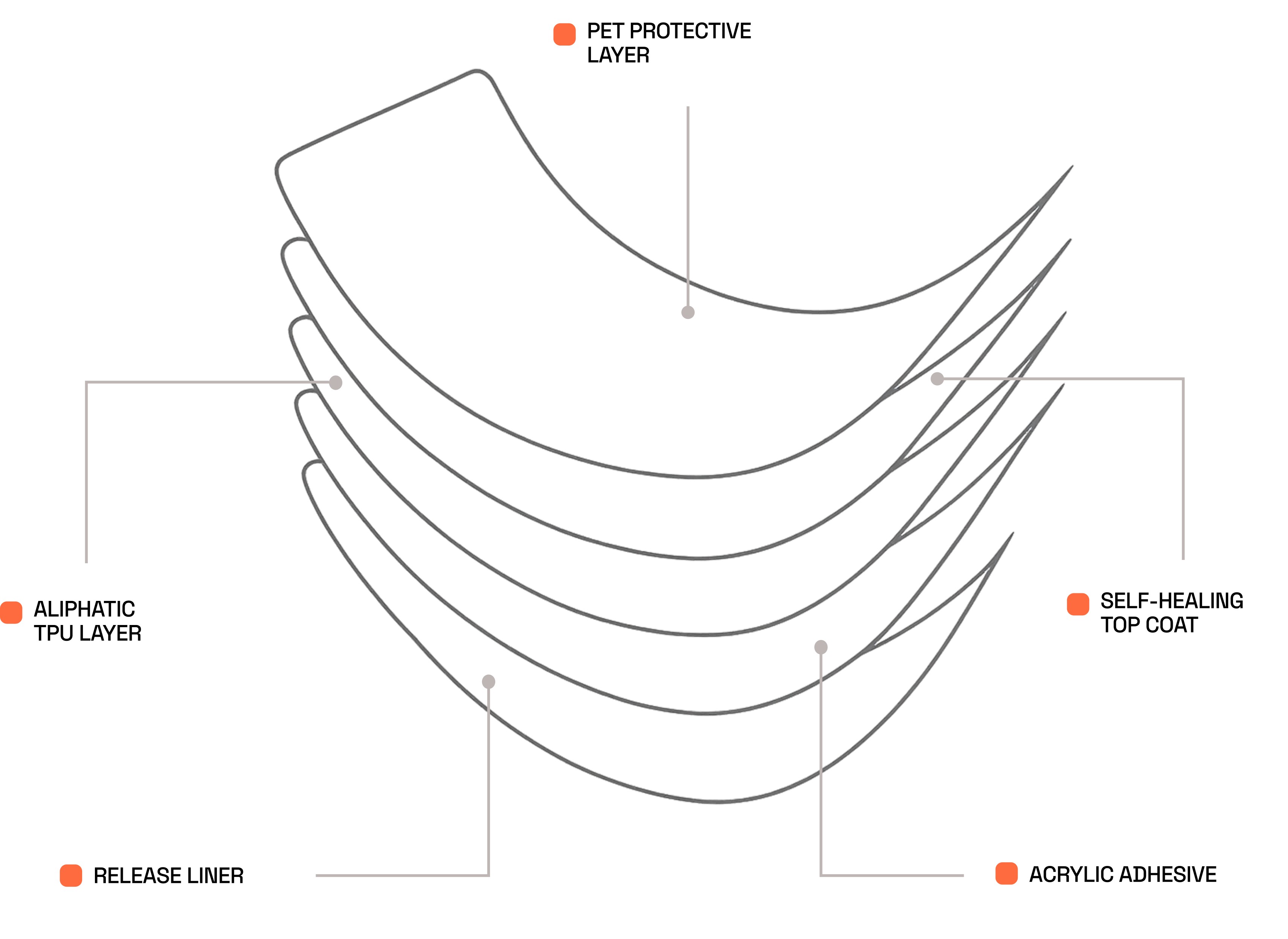

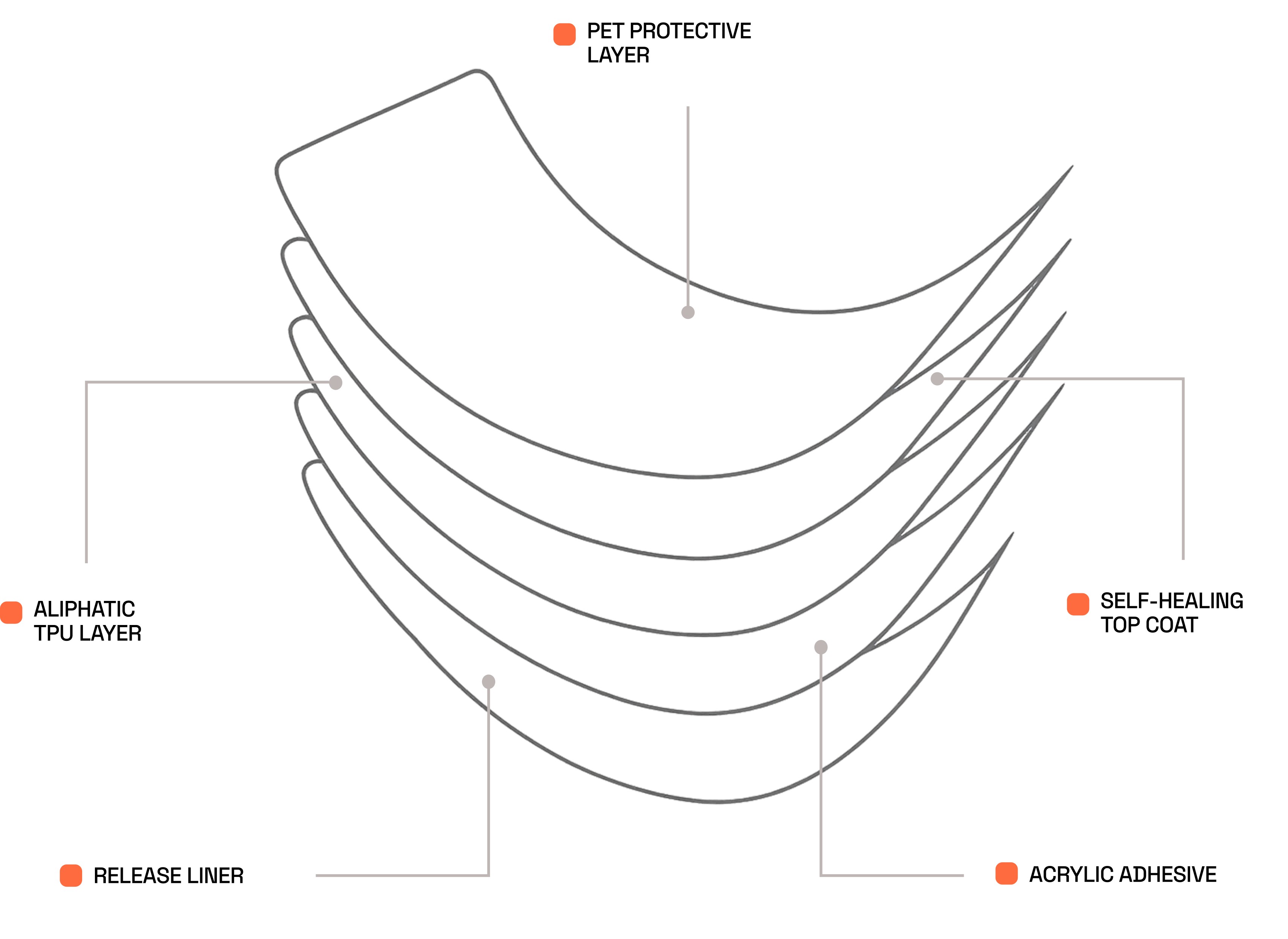

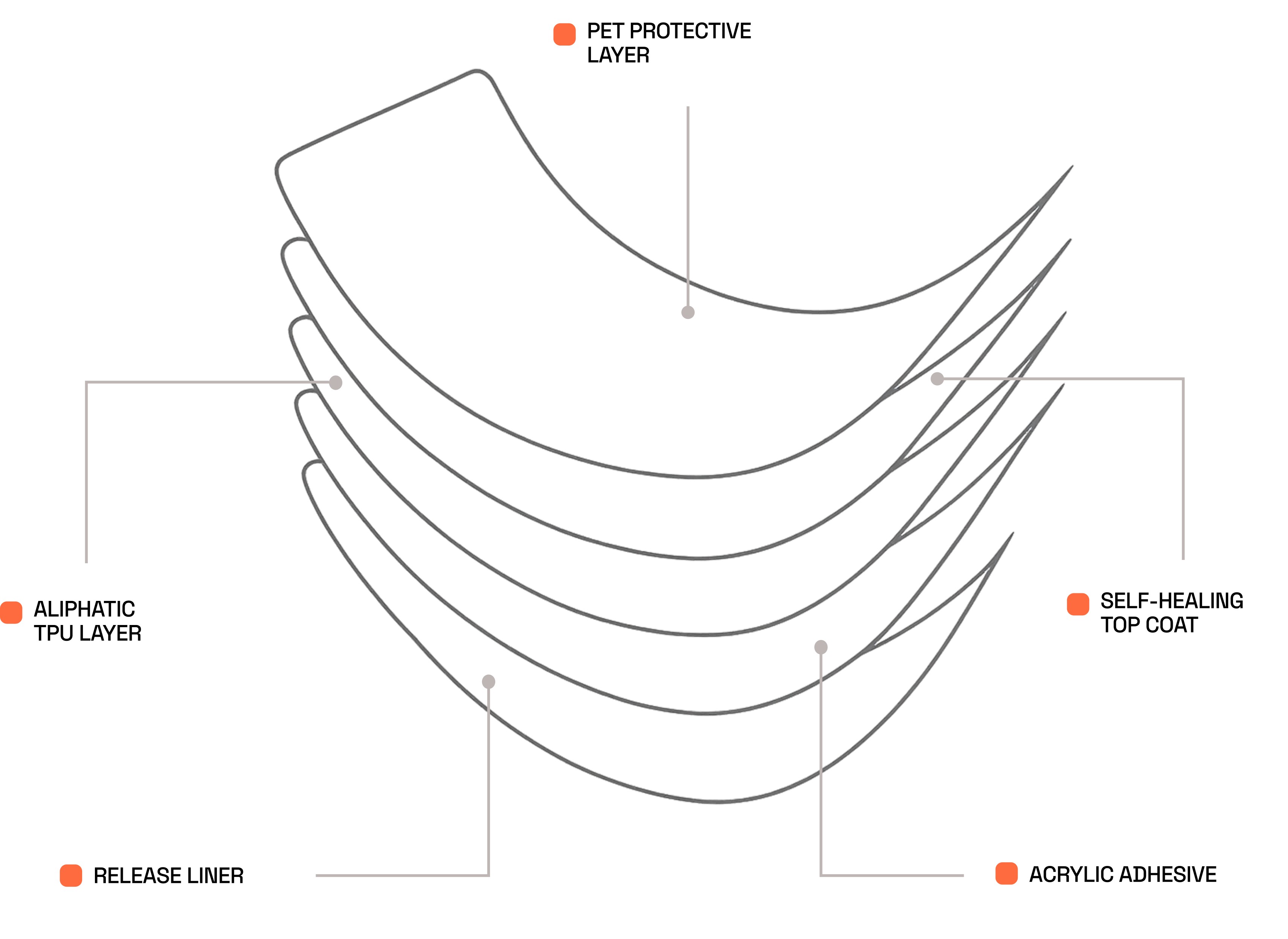

Layers

OUR LAYERED CONSTRUCTION

Made to Go Further.

Every ARGUX film is built from a multi layer structure engineered to work as one combining a self healing top coat, high clarity TPU core, and premium adhesive system to deliver lasting durability, stronger impact resistance, and long term optical clarity. Each layer is purpose built to protect your paint from UV, debris, and daily wear while maintaining a flawless, high performance finish.

KEEP YOUR PAINT LOOKING NEW

KEEP YOUR PAINT LOOKING NEW

KEEP YOUR PAINT LOOKING NEW

KEEP YOUR PAINT LOOKING NEW

Products

ARGUX Core

ARGUX Prime

ARGUX Ultra

ARGUX Velare

Discover

Contact

info@argux.com.au

3/10 Islington Court Dudley Park SA 5008

Socials

Standards and Certifications

© 2025 ARGUX.All rights reserved

Products

ARGUX Core

ARGUX Prime

ARGUX Ultra

ARGUX Velare

Discover

Contact

info@argux.com.au

3/10 Islington Court Dudley Park SA 5008

Socials

Standards and Certifications

© 2025 ARGUX.All rights reserved

Products

ARGUX Core

ARGUX Prime

ARGUX Ultra

ARGUX Velare

Discover

Contact

info@argux.com.au

3/10 Islington Court Dudley Park SA 5008

Socials

Standards and Certifications

© 2025 ARGUX.All rights reserved

Standards and Certifications

© 2025 ARGUX.All rights reserved

HOW ARGUX PPF IS MADE

TRANSFORMING RAW TPU INTO FILM BUILT TO ENDURE REAL ROADS.

STEP 3

Self-Healing Top Coating

A high performance nano ceramic top coat is added, giving the film heat activated self healing properties, stronger stain resistance, and exceptional clarity over time.

STEP 4

PET Protective Lamination

We laminate the film with a stabilising PET protective layer, ensuring strength during handling and perfectly preserving the surface until installation.

STEP 5

Curing, Cutting & Packaging

Every layer undergoes a controlled curing cycle, then the film is cut into 15m × 1.52m rolls, inspected for quality, and packaged for distribution.

STEP 1

TPU Extrusion

We begin with German engineered BASF aliphatic TPU, melted and extruded into a flawless 605 meter sheet. This forms the foundation of every ARGUX film pure, strong, and optically clear.

STEP 2

Adhesive Coating

The TPU sheet moves into a dedicated coating line where a precision applied high bond acrylic adhesive is deposited, engineered for clean installation, strong adhesion, and long term durability.

STEP 3

Self-Healing Top Coating

A high performance nano ceramic top coat is added, giving the film heat activated self healing properties, stronger stain resistance, and exceptional clarity over time.

STEP 4

PET Protective Lamination

We laminate the film with a stabilising PET protective layer, ensuring strength during handling and perfectly preserving the surface until installation.

STEP 5

Curing, Cutting & Packaging

Every layer undergoes a controlled curing cycle, then the film is cut into 15m × 1.52m rolls, inspected for quality, and packaged for distribution.

STEP 2

Adhesive Coating

The TPU sheet moves into a dedicated coating line where a precision applied high bond acrylic adhesive is deposited, engineered for clean installation, strong adhesion, and long term durability.

STEP 1

TPU Extrusion

We begin with German engineered BASF aliphatic TPU, melted and extruded into a flawless 605 meter sheet. This forms the foundation of every ARGUX film - pure, strong, and optically clear.

STEP 2

Adhesive Coating

The TPU sheet moves into a dedicated coating line where a precision applied high bond acrylic adhesive is deposited, engineered for clean installation, strong adhesion, and long term durability.

STEP 4

PET Protective Lamination

We laminate the film with a stabilising PET protective layer, ensuring strength during handling and perfectly preserving the surface until installation.

STEP 5

Curing, Cutting & Packaging

Every layer undergoes a controlled curing cycle, then the film is cut into 15m × 1.52m rolls, inspected for quality, and packaged for distribution.

STEP 1

TPU Extrusion

We begin with German engineered BASF aliphatic TPU, melted and extruded into a flawless 605 meter sheet. This forms the foundation of every ARGUX film - pure, strong, and optically clear.

STEP 3

Self-Healing Top Coating

A high performance nano ceramic top coat is added, giving the film heat activated self healing properties, stronger stain resistance, and exceptional clarity over time.

STEP 1

TPU Extrusion

We begin with German engineered BASF aliphatic TPU, melted and extruded into a flawless 605 meter sheet. This forms the foundation of every ARGUX film — pure, strong, and optically clear.

STEP 2

Adhesive Coating

The TPU sheet moves into a dedicated coating line where a precision applied high bond acrylic adhesive is deposited, engineered for clean installation, strong adhesion, and long term durability.

STEP 3

Self-Healing Top Coating

A high performance nano ceramic top coat is added, giving the film heat activated self healing properties, stronger stain resistance, and exceptional clarity over time.

STEP 4

PET Protective Lamination

We laminate the film with a stabilising PET protective layer, ensuring strength during handling and perfectly preserving the surface until installation.

STEP 5

Curing, Cutting & Packaging

Every layer undergoes a controlled curing cycle, then the film is cut into 15m × 1.52m rolls, inspected for quality, and packaged for distribution.

STEP 1

TPU Extrusion

We begin with German engineered BASF aliphatic TPU, melted and extruded into a flawless 605 meter sheet. This forms the foundation of every ARGUX film — pure, strong, and optically clear.

STEP 2

Adhesive Coating

The TPU sheet moves into a dedicated coating line where a precision applied high bond acrylic adhesive is deposited, engineered for clean installation, strong adhesion, and long term durability.

STEP 3

Self-Healing Top Coating

A high performance nano ceramic top coat is added, giving the film heat activated self healing properties, stronger stain resistance, and exceptional clarity over time.

STEP 4

PET Protective Lamination

We laminate the film with a stabilising PET protective layer, ensuring strength during handling and perfectly preserving the surface until installation.

STEP 5

Curing, Cutting & Packaging

Every layer undergoes a controlled curing cycle, then the film is cut into 15m × 1.52m rolls, inspected for quality, and packaged for distribution.

STEP 1

TPU Extrusion

We begin with German engineered BASF aliphatic TPU, melted and extruded into a flawless 605 meter sheet. This forms the foundation of every ARGUX film — pure, strong, and optically clear.

STEP 2

Adhesive Coating

The TPU sheet moves into a dedicated coating line where a precision applied high bond acrylic adhesive is deposited, engineered for clean installation, strong adhesion, and long term durability.

STEP 3

Self-Healing Top Coating

A high performance nano ceramic top coat is added, giving the film heat activated self healing properties, stronger stain resistance, and exceptional clarity over time.

STEP 4

PET Protective Lamination

We laminate the film with a stabilising PET protective layer, ensuring strength during handling and perfectly preserving the surface until installation.

STEP 5

Curing, Cutting & Packaging

Every layer undergoes a controlled curing cycle, then the film is cut into 15m × 1.52m rolls, inspected for quality, and packaged for distribution.

STEP 1

TPU Extrusion

We begin with German engineered BASF aliphatic TPU, melted and extruded into a flawless 605 meter sheet. This forms the foundation of every ARGUX film — pure, strong, and optically clear.

STEP 2

Adhesive Coating

The TPU sheet moves into a dedicated coating line where a precision applied high bond acrylic adhesive is deposited, engineered for clean installation, strong adhesion, and long term durability.

STEP 3

Self-Healing Top Coating

A high performance nano ceramic top coat is added, giving the film heat activated self healing properties, stronger stain resistance, and exceptional clarity over time.

STEP 4

PET Protective Lamination

We laminate the film with a stabilising PET protective layer, ensuring strength during handling and perfectly preserving the surface until installation.

STEP 5

Curing, Cutting & Packaging

Every layer undergoes a controlled curing cycle, then the film is cut into 15m × 1.52m rolls, inspected for quality, and packaged for distribution.

WHY INHOUSE

Built by Us. Controlled by Us. Perfected by Us.

Total Material Control

We select every ingredient from German-made TPU to our adhesive formulation ensuring consistent clarity, strength, and long-term performance.

precison at every step

We select every ingredient from German-made TPU to our adhesive formulation ensuring consistent clarity, strength, and long-term performance.

Better durability and Stability

In-house production guarantees uniform thickness, clarity, and adhesive performance — giving installers predictable results and drivers long-term reliability.

Consistency across every roll

In-house production guarantees uniform thickness, clarity, and adhesive performance — giving installers predictable results and drivers long-term reliability.

Total Material Control

We begin with German engineered BASF aliphatic TPU, melted and extruded into a flawless 605 meter sheet. This forms the foundation of every ARGUX film pure, strong, and optically clear.

Precison at every step

Extrusion, coating, curing, and cutting all happen under one roof. Nothing is left to chance, and every layer meets our internal standards.

Better durability and Stability

In-house production allows us to fine tune UV resistance, healing speed, stain resistance, and elasticity for harsher climates like Australia.

Consistency across every roll

In-house production guarantees uniform thickness, clarity, and adhesive performance giving installers predictable results and drivers long term reliability.

WHY INHOUSE

Built by Us. Controlled by Us. Perfected by Us.

Total Material Control

We begin with German engineered BASF aliphatic TPU, melted and extruded into a flawless 605 meter sheet. This forms the foundation of every ARGUX film pure, strong, and optically clear.

Precison at every step

Extrusion, coating, curing, and cutting all happen under one roof. Nothing is left to chance, and every layer meets our internal standards.

Better durability and Stability

In-house production allows us to fine tune UV resistance, healing speed, stain resistance, and elasticity for harsher climates like Australia.

Consistency across every roll

In-house production guarantees uniform thickness, clarity, and adhesive performance giving installers predictable results and drivers long term reliability.

WHY INHOUSE

Built by Us. Controlled by Us. Perfected by Us.

Total Material Control

We begin with German engineered BASF aliphatic TPU, melted and extruded into a flawless 605 meter sheet. This forms the foundation of every ARGUX film pure, strong, and optically clear.

Precison at every step

Extrusion, coating, curing, and cutting all happen under one roof. Nothing is left to chance, and every layer meets our internal standards.

Better durability and Stability

In-house production allows us to fine tune UV resistance, healing speed, stain resistance, and elasticity for harsher climates like Australia.

Consistency across every roll

In-house production guarantees uniform thickness, clarity, and adhesive performance giving installers predictable results and drivers long term reliability.

WHY INHOUSE

Built by Us. Controlled by Us. Perfected by Us.

Total Material Control

We begin with German engineered BASF aliphatic TPU, melted and extruded into a flawless 605 meter sheet. This forms the foundation of every ARGUX film pure, strong, and optically clear.

Precison at every step

Extrusion, coating, curing, and cutting all happen under one roof. Nothing is left to chance, and every layer meets our internal standards.

Better durability and Stability

In-house production allows us to fine tune UV resistance, healing speed, stain resistance, and elasticity for harsher climates like Australia.

Consistency across every roll

In-house production guarantees uniform thickness, clarity, and adhesive performance — giving installers predictable results and drivers long-term reliability.

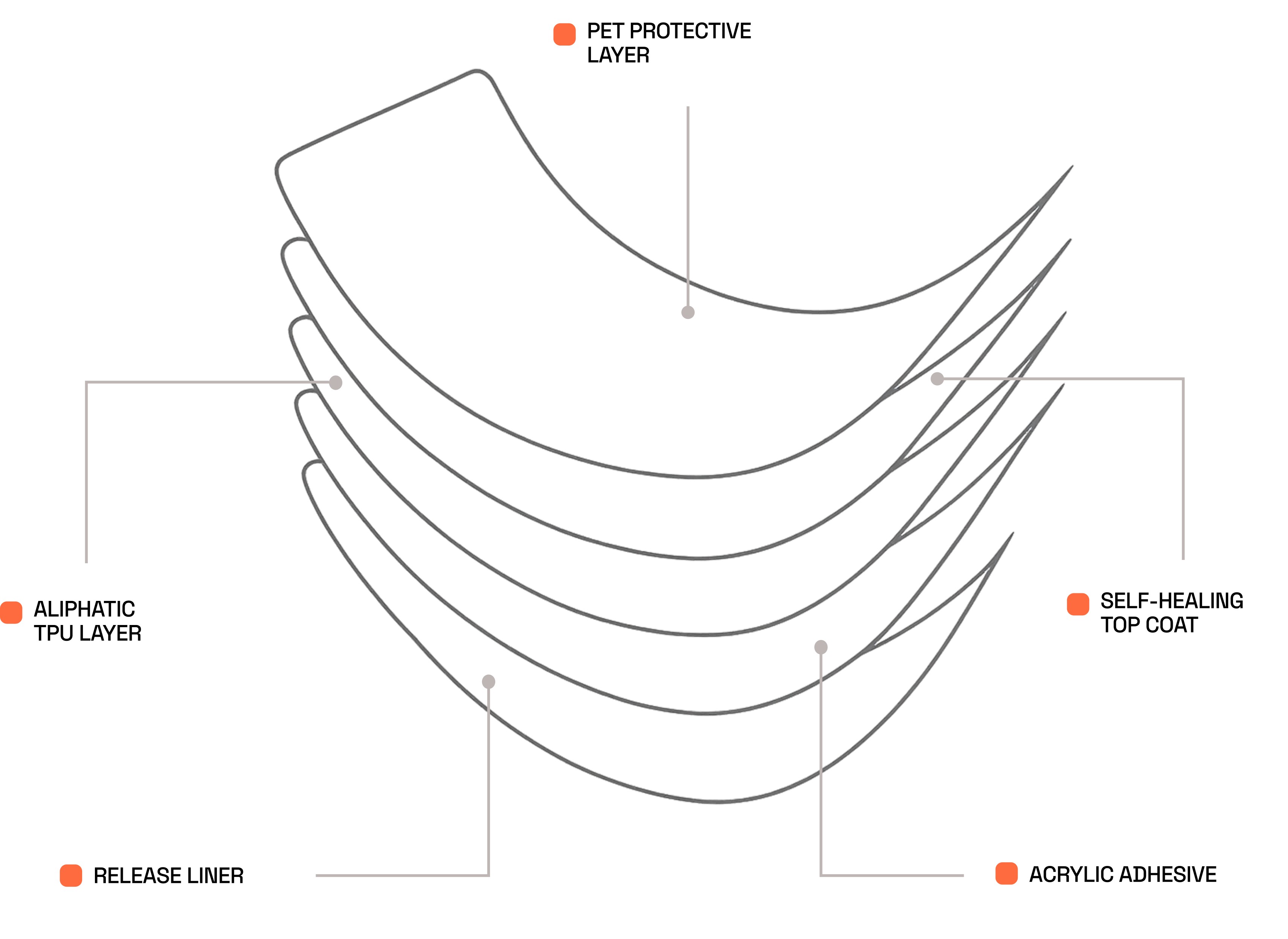

Layers

OUR LAYERED CONSTRUCTION

Made to Go Further.

Every ARGUX film is built from a multi layer structure engineered to work as one combining a self healing top coat, high clarity TPU core, and premium adhesive system to deliver lasting durability, stronger impact resistance, and long term optical clarity. Each layer is purpose built to protect your paint from UV, debris, and daily wear while maintaining a flawless, high performance finish.

KEEP YOUR PAINT LOOKING NEW

Standards and Certifications

© 2025 ARGUX.All rights reserved